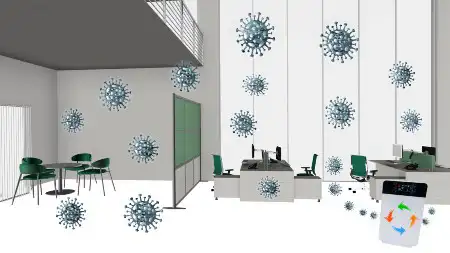

It is common for people to associate air pollution with outdoor spaces. However, indoor air quality can deteriorate just as much. In commercial buildings, indoor air quality matters, from how it affects customers and employees to keeping with the industry rules and regulations. This article highlights the importance of maintaining indoor air quality, indoor air quality testing, and where the rules and regulations apply.

What is indoor air quality testing?

Indoor air quality refers to the composition of different elements in the air and how they affect the health and wellbeing of a building’s occupants.

Testing air quality is essential, considering people spend most of their time indoors. Also, contaminants in the air like dust, dirt, and dangerous gases can cause respiratory complications like asthma and lung cancer.

Indoor air quality receives so much attention, mainly because most commercial premises use ventilation systems the design of which presents a contamination challenge. Therefore, you need to be keen on your premises’ indoor air quality to keep your employees and customers safe.

The indoor air quality testing process

This section covers the steps necessary in testing indoor air quality on commercial premises:

Pre-test assessment

A survey of the premises is necessary before any testing. It focuses on:

• The type of building and its age

• The building materials used in its construction

• Average occupant population and density

• Operational ventilation system

• Presence of equipment or other commodities that could release potentially harmful air contaminants

• Cleaning systems and procedures

• Preliminary check for mould, dust, and foul smell

The information gathered informs the indoor air quality testing professionals on which procedure to adopt in the testing exercise.

Determining the testing sites

The testing then commences once the analytical team decide which sample locations on the premises are suitable for testing. Air quality differs in different locations of the premises, so it is crucial to pick several spots for the tests, using the information gathered from the preliminary assessment.

Applying testing methodologies

There are many testing methodologies. They are categorised as follows:

• Chemical testing: This testing entails three options. Comprehensive total VOC (volatile organic compounds) testing, which uses a parts-per-billion photo-ionising detector, broad specific VOC testing, and specific VOC testing.

• Gas testing: This testing technique checks for different gases in the air and their levels. Examples include CO2, CO,SO2, petroleum gases, hydrogen cyanide, formaldehyde and combustion by-products like carbon monoxide and hydrogen sulphide. CO2 testing is especially critical as high levels mean the ventilation system isn’t operating optimally.

• Biological testing: This testing checks for mould, bacteria, fungi, spores and allergens like pollen and dust mites.

• Particulate testing: This testing involves soot analysis, dust analysis, filtration evaluations, etc.

A highly experienced indoor air quality service provider has the right equipment to collect samples and data for the next step which is the lab analysis.

Laboratory analysis

Testing procedures that necessitate sample collection will see the air quality engineers head to the lab for analysis. The resultant laboratory reports give a detailed and independent account of the present air quality and recommendations on how to minimise or remove current contaminants to improve indoor air quality.

Where is indoor air quality testing a priority?

While there are arguments on which commercial premises need air quality testing, the answer is simple. Any building with occupants, regular or otherwise, or storage areas where people are likely to frequent, need indoor air quality testing. Commercial premises that rely on ventilation systems especially need these tests.

Outside flowing air in general tends to contain fewer contaminants. However, this doesn’t mean that premises where all windows are always open don’t need air quality testing. There is always a chance that contaminants are floating in the air, ready to wreak havoc on the occupant’s health.

What rules and regulations govern indoor air quality testing?

Businesses maintain their premises under local and national authority rules and regulations. These rules and regulations ensure the safety of all occupants and help promote health and wellbeing with a vision of sustainability in business. The Health & Safety & Welfare at Work 1999 Act gives directives on how companies should maintain indoor air quality on their premises. The Act touches on several factors, all focused on cleanliness, regular inspection, and maintenance of ventilation systems.

Why is indoor air quality testing necessary?

Besides complying with industry and government rules and regulations, here are other reasons why you need to prioritise this exercise:

To safeguard the health of occupants

It’s no secret that poor air quality directly affects the occupants’ health and thus their productivity. Workers who constantly suffer from respiratory irritations and illnesses need more time off, focus less on their tasks, and are likely to offer poor customer service. Indoor air quality testing provides solutions to improve and maintain quality air indoors, thus keeping all occupants healthy and operating at optimum levels.

To minimise operational expenses

Poor air quality could be the result of a malfunctioning ventilation system. Identifying its problem areas after the testing helps maintain it at its optimum operating levels. Such an efficiently operating system uses less electricity thus cutting down on energy bills. In addition, repair, replacement, and maintenance costs will be lower, which translates to lower operational expenses for the business.

To improve your competitive edge

Besides a happier and healthier workforce, improving indoor air quality makes for pleasant premises. Visiting customers will have one more reason to frequent your business, thus reducing the impact of your competition. Remember, customers can easily walk away after the slightest provocation, such as a foul smell on your premises.

Conclusion

Indoor air quality testing in your business premises is vital in maintaining a conducive environment for all occupants. Complying with industry standards, rules, and regulations helps keep your employees and customers safe, healthy, and happy. Such a pleasant environment improves employee performance and gives customers another reason to visit you. You should ensure that you use the best indoor air quality testing service. One that understands the complexities of the process and has the right expertise and equipment to do a stellar job, such as the team at VSS.

Ventilation Surveys & Services, 305/307 Tower Street, Century Buildings – Brunswick Business Park, Liverpool, Merseyside, L3 4BJ

Company Registration Number 07411775

VAT – 997895709

© 2025 Ventilation Surveys & Services Limited | Website by Xanthos